Project Summary

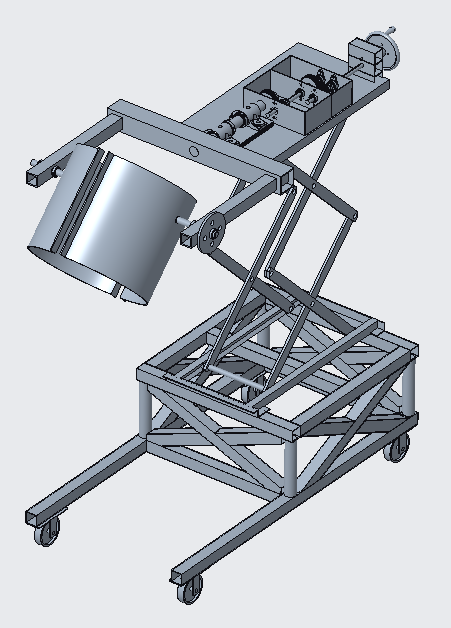

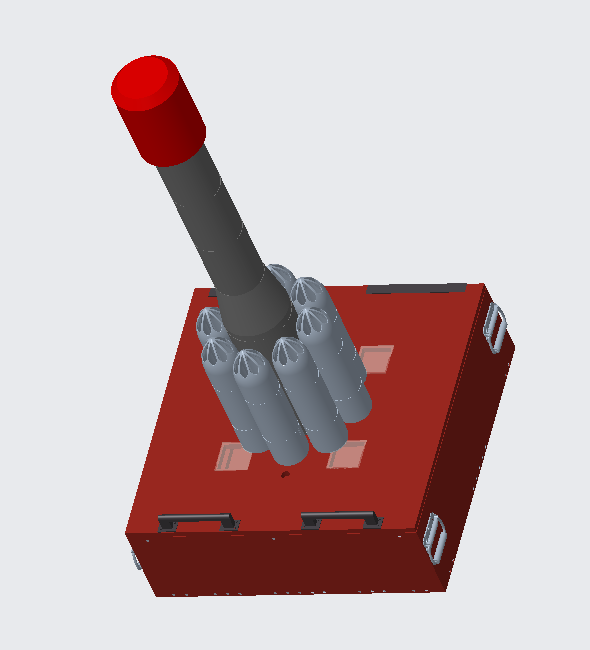

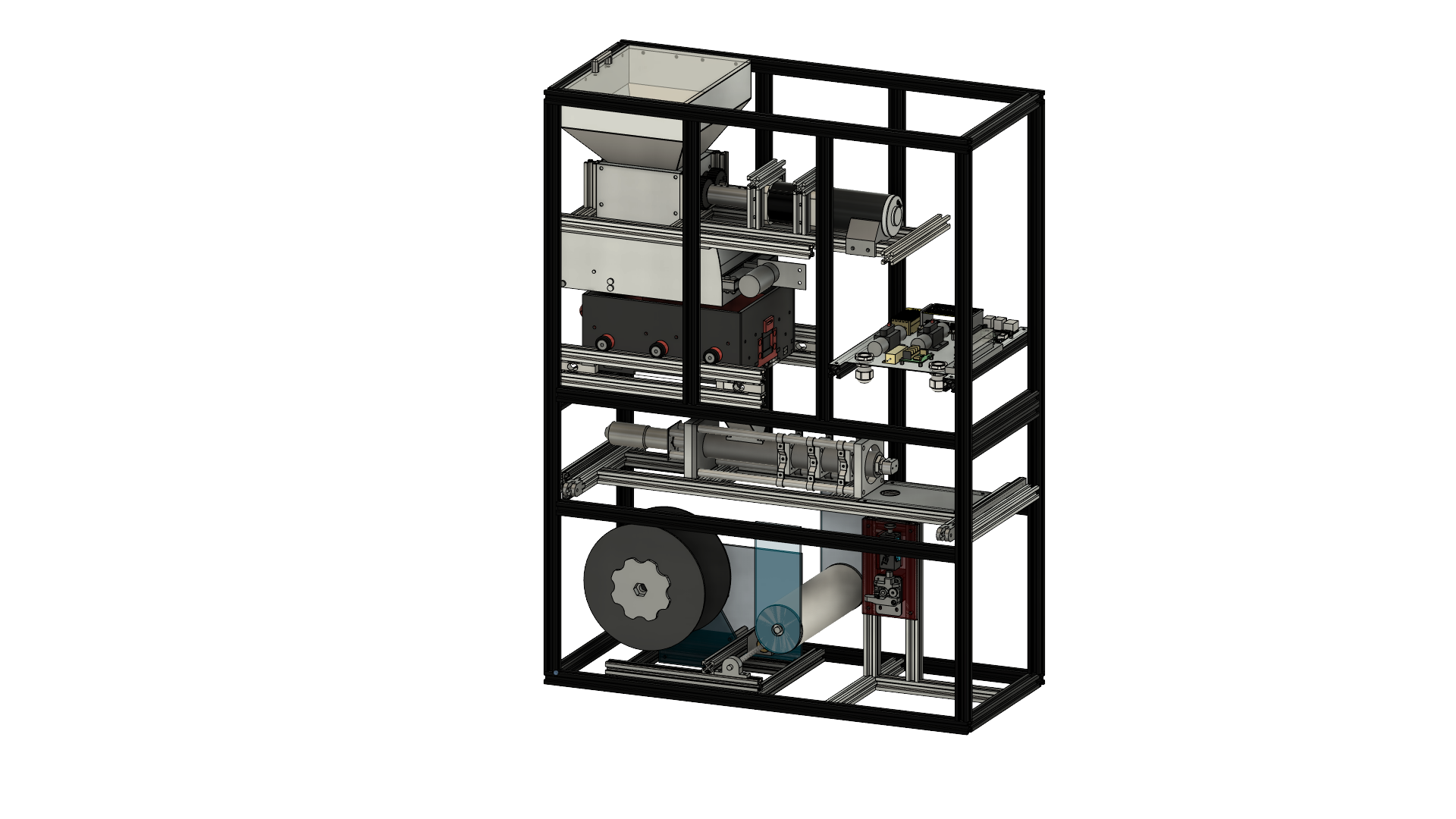

The L3HSDC requested a machine capable of recycling its large amount of scrap PLA plastic into reusable filament for their 3D printers. Our team was tasked with designing, building, and testing this recycling machine, which needed to break down the plastic into small pieces, melt those pieces into a molten state, extrude the melted plastic into filament, and wrap it onto a standard filament spool. In order to accomplish this, the project was divided into three main subsystems: Reducer, Producer, and Automation and Controls. The Reducer consists of all components integral to the breaking down, filtering, and storing of the plastic. The Producer consists of all components integral to melting, extruding, checking diameter, and spooling the plastic. Automation and Controls ties all components together by controlling electronics and mechanical assemblies, as well as constantly monitoring safety parameters.

Project Objective

This recycling machine must take the customer’s discarded PLA plastic as input and output recycled PLA filament. To accomplish this, the plastic is shredded into very small pieces for uniform melting. The shredded plastic then enters a filtering mechanism before being held in a storage container. Upon process start, the small plastic pieces are fed into the extrusion mechanism, similar to injection molding technology, which melts down the solid plastic pieces into molten PLA. Once melted fully, the plastic is compressed and extruded as a continuous strand of recycled filament. This new filament is then measured to ensure the diameter is the same as the standard diameter for 3D printing filament. Finally, the recycled filament is wrapped onto a standard 3D printing spool via the spooling mechanism.

The recycling machine is designed to be composed primarily of commercially available parts to ensure that the customer has little to no issues when finding replacements for worn or damaged components. Due to the dangerous nature of this machine and its various mechanisms, there are numerous safety barriers in place to ensure user safety while the machine is active. There are also safety parameters that continuously check data against nominal values in order to catch any system irregularities, such as overheating or motor malfunction. Additionally, the team is providing the customer with an operation manual, which includes safety guidelines, as well as a maintenance plan outlining the required service the product will need to ensure maximum safety, efficiency, and longevity when operating.

Manufacturing Design Methods

The largest challenge faced during the design and manufacturing of the recycler was attempting to create prototypes early in the design process. The goal of this was to address any design flaws that may have presented themselves, as well as to have more time if it was necessary to pursue a whole new design approach. Using heat analysis and static structural analysis in both Fusion 360 and ANSYS Workbench were essential when ensuring our designs were fully informed. Iterative design was the key to this project, as the CAD models for each of the core components of the machine were continually updated and improved upon until the final designs were solidified. However, this meant the design stage lasted longer than scheduled, which proved detrimental to our progress over time.

Manufacturing for this project consisted primarily of using the water jet machine to cut out metal parts. Many parts for our Producer components were machined by hand or using the CNC mill. Any other parts that were custom designed were made using 3D printers. Prototypes in the early stage of the project also used 3D printed parts, as well as wood and acrylic parts cut on the large-format laser cutters.

Specification

Weight: ~150 lb.

Size: 0.70m W x 0.94m H x 0.30m D (27.6" W x 37.0" H x 11.8" D)

Storage capabilities: up to 2.5 kg of shredded PLA

Process time (1 kg):

Analysis

Heat analysis and static structural analysis in both Fusion 360 and ANSYS Workbench were used when designing most parts due to the high temperatures inside a section of the machine. Calculations were done by hand as well as in Excel to determine torque and force in the shredder mechanism, as well as when determining rotation and translation speeds for the spooling mechanism.

Future Works

In the future, the final design for our machine could be improved upon as it is used in the L3Harris Student Design Center. Troubleshooting opportunities may arise that could require some redesigning of parts or slight modifications to system function.

Manufacturing Design Methods

The largest challenge faced during the design and manufacturing of the recycler was attempting to create prototypes early in the design process. The goal of this was to address any design flaws that may have presented themselves, as well as to have more time if it was necessary to pursue a whole new design approach. Using heat analysis and static structural analysis in both Fusion 360 and ANSYS Workbench were essential when ensuring our designs were fully informed. Iterative design was the key to this project, as the CAD models for each of the core components of the machine were continually updated and improved upon until the final designs were solidified. However, this meant the design stage lasted longer than scheduled, which proved detrimental to our progress over time.

Manufacturing for this project consisted primarily of using the water jet machine to cut out metal parts. Many parts for our Producer components were machined by hand or using the CNC mill. Any other parts that were custom designed were made using 3D printers. Prototypes in the early stage of the project also used 3D printed parts, as well as wood and acrylic parts cut on the large-format laser cutters.

![]()