Northrop Grumman Engineering & Science Student Design Showcase

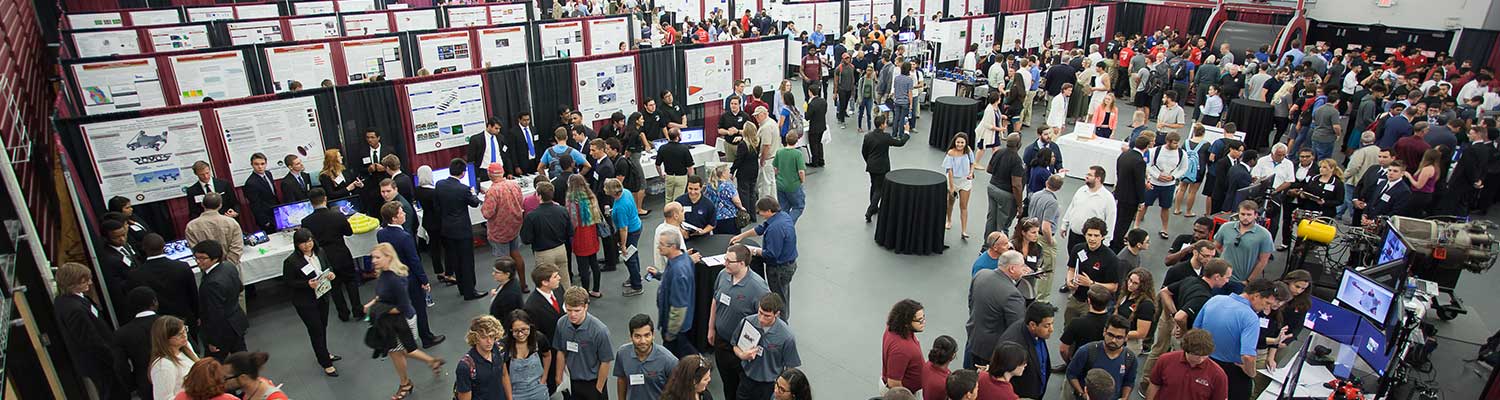

Welcome to the Northrop Grumman Engineering & Science Student Design Showcase at Florida Tech, an annual event during which student teams present their work and field questions from their peers, faculty members, industry professionals and local leaders.

For graduating seniors, the event represents years of coursework and hands-on learning experiences put to the test through project-based learning. As the central element of students’ final capstone course, Senior Design provides an engaging context for learning, an opportunity to integrate complex material and the inspiration to discover new ways of thinking and doing.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)