Project Summary

Hundreds of thousands of people have conditions that affect their upper body movement, ranging from cerebral palsy to stroke rehabilitation patients to patients who had been in accidents that affected their upper extremities. This causes a disconnect between the patient's mind and body, which is extremely detrimental to the patient's mental health. The ExoArm is a myoelectric exoskeleton arm brace that utilizes an EMG sensor to collect the electrical signals from the arm muscles to control motors that move the brace to mimic the arm's movement. By using the patients' muscle signals to control the brace, the ExoArm is designed to be an extension of the arm that amplifies the patients' strength. The ExoArm uses machine learning to classify the motions of the patient's arm to accurately and quickly convert it into mechanical motion in the brace.

Project Objective

The objective of the ExoArm was to design and manufacture a myoelectric exoskeleton brace that amplifies a patient's arm strength to enable them to regain a full range of motion. The ExoArm sought to be completely customizable- from the setup code for the brace's movement so it is specified to its user to the brace's length. This brace aims to be comfortable enough for all-day wear and have all components completely wearable, without the need to be plugged in during use. Another goal of the ExoArm was to minimize the timing delay from the muscle activation to the brace's movement.

Manufacturing Design Methods

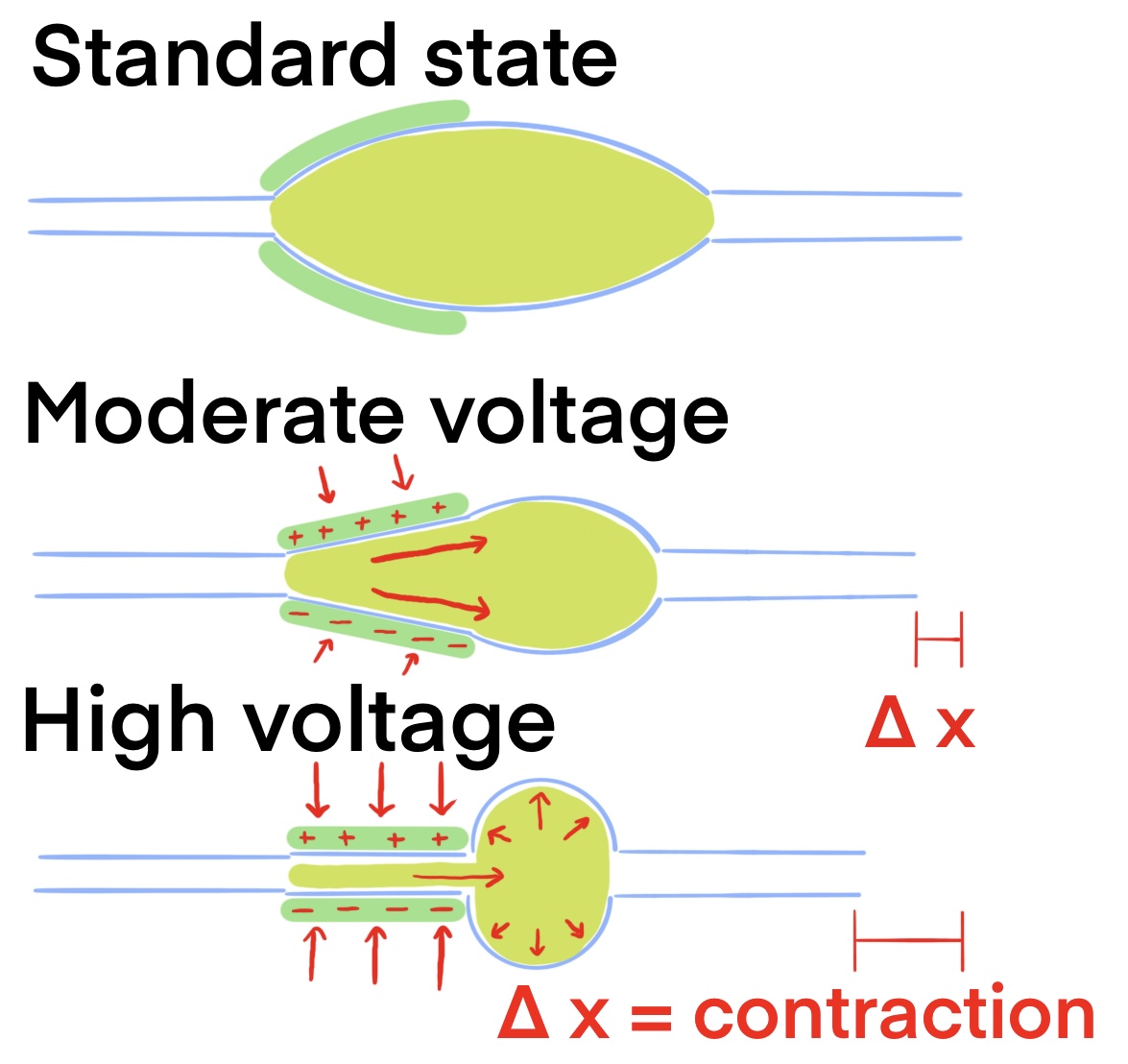

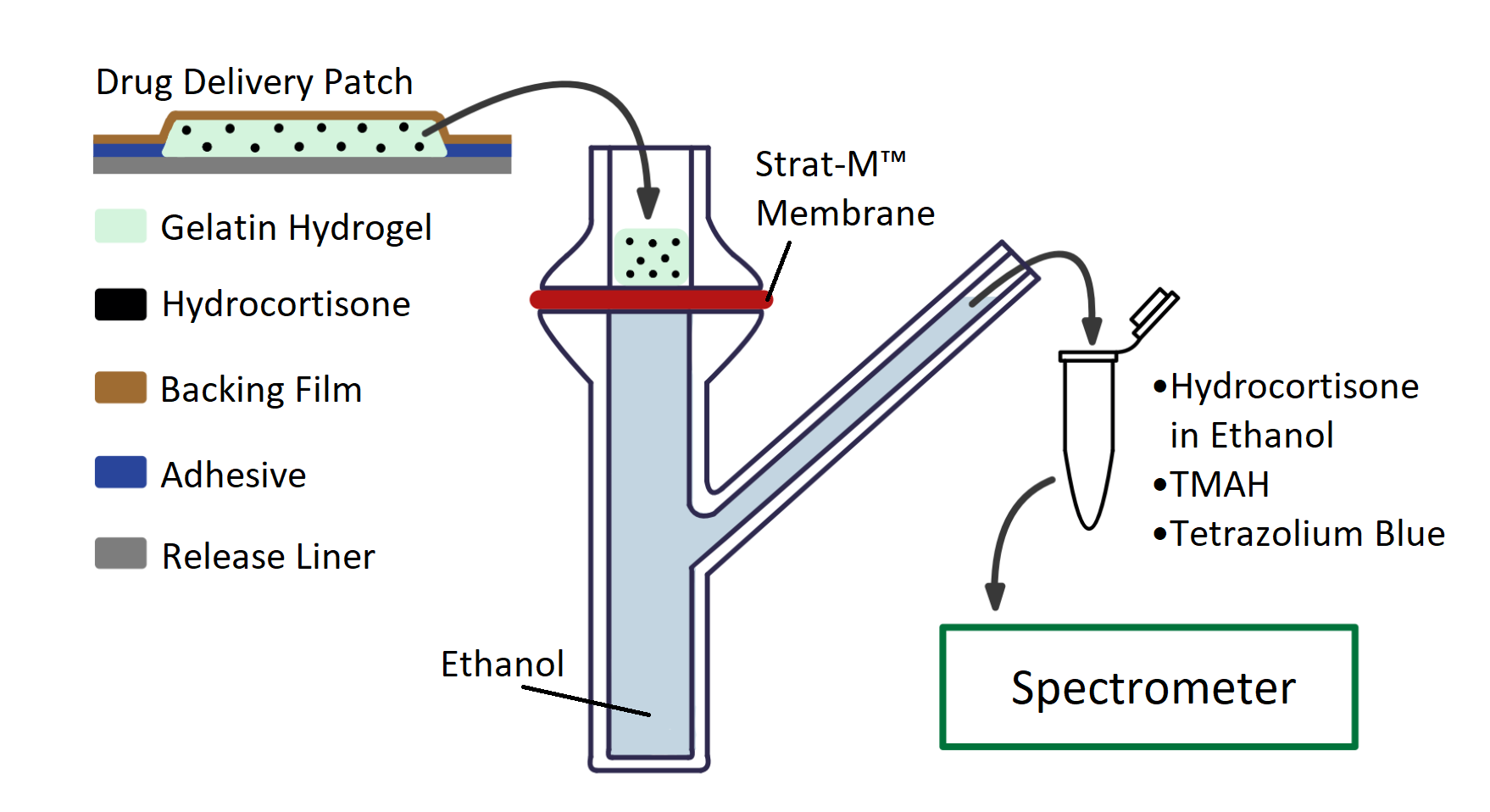

During the hardware testing stages, an initial design for the brace with drafted with consideration of the weight requirements, mobility, and comfort. The iterated designs were 3D printed and assembled for further structural integrity testing. The design cycled through multiple models; the most significant changes being to the hand to enable the patient to grip and to the elbow to ensure comfort and optimize the range of motion. The hand mechanism was altered so that the movement of the fingers was controlled by the wrist so that patients who have lost fine motor skills can regain their grip strength. During software testing, EMG data was collected from several participants to determine the patterns in the signal, and different methods were tested to determine the best signal-to-motion classification system. In the end, the brace will use machine learning to identify the motion from the signal and output a position to the brace. The brace is similar to some devices that are already on the market and FDA-approved, so our product is predicted to have high success with the various improvements made. The design was predominantly 3D printed for cost-effectiveness and customizability.

Specification

The specifications for this project include: being able to lift 50 pounds, having a less than 1-second delay between muscle and brace movement, being comfortable for long-term wear, being customizable for different patients, having a 160º range of motion, having accurate movements from the muscle signal data from EMG sensor, having an entirely wearable design, being more affordable than the competition, and having a lightweight design.

Analysis

The data analysis for the hardware was predominantly trying to simulate how the brace would be used in day-to-day life and determine what improvements would be necessary. With each adjustment and improvement to the design, force calculations, biomechanical motion range, and functionality of the user had to be re-examined. For the software, data analysis consisted of determining the best sensor type and placement, understanding the patterns of the EMG waveforms for different motions, and extracting features that have the most correlation to motion. A process of trial and error and visual patterns was used to determine the thresholds of the different features. The movement of the brace, as controlled by the code, was compared against a protractor to ensure the theoretical and actual movements were equivalent. Later, a position sensor was used to record real-time data while also getting the angle of the arm. This data was put into a machine learning model to test the accuracy of classification using XGBoost. With two motions, the accuracy of the predicted motion was 86%, while the accuracy with three motions was 77%. Feature Importance in machine learning was also used to determine the significance of the selected features to the motion results. Through this, it was determined that the bicep muscle was more significant than the tricep, and all features used had high correlations to the motion of the arm.

Future Works

Throughout our research and manufacturing process, we developed several different designs to improve functionality. In the future, several improvements could be made to the current design to better assist patients in day-to-day life. For software, advancing the machine learning algorithm will make the responses faster and more accurate. Additionally, including rehabilitation features to simulate a therapy session could aid in patients' recovery. Creating a Bluetooth connection and app would make the brace smarter and easier to use. For hardware, designing the brace to have more adjustable settings would make the brace more inclusive for all ages. Choosing more optimal biomaterials for the brace would increase its integrity and durability.

Other Information

Since the inception of the project, the ExoArm team has had a donation link for the cerebral palsy foundation and has raised over 400 dollars toward cerebral palsy research.

Watch our Project Video: https://youtu.be/dXDNjwDAp0s

Manufacturing Design Methods

During the hardware testing stages, an initial design for the brace with drafted with consideration of the weight requirements, mobility, and comfort. The iterated designs were 3D printed and assembled for further structural integrity testing. The design cycled through multiple models; the most significant changes being to the hand to enable the patient to grip and to the elbow to ensure comfort and optimize the range of motion. The hand mechanism was altered so that the movement of the fingers was controlled by the wrist so that patients who have lost fine motor skills can regain their grip strength. During software testing, EMG data was collected from several participants to determine the patterns in the signal, and different methods were tested to determine the best signal-to-motion classification system. In the end, the brace will use machine learning to identify the motion from the signal and output a position to the brace. The brace is similar to some devices that are already on the market and FDA-approved, so our product is predicted to have high success with the various improvements made. The design was predominantly 3D printed for cost-effectiveness and customizability.

![]()

.png)