6 Surprising Logistics Careers

Drones | Predictive Modeling | 3-D Printing | Sustainability | Military | Disaster Relief | Companies Love Logistics Majors

Did You Know? Logistics is a Greek word that means “skilled in calculating.”

Drones, 3-D printing and disaster relief are just a few of the logistics careers available to logistics majors.

You hear the term a lot these days on TV commercials and in taglines. Getting products where they need to be is a part of logistics, but there are a lot more opportunities in the field as technology continues to advance. Now is the time to check out what’s coming and get the skills you need to land a job that will be in demand for years to come.

1. Drones

Unmanned delivery platforms might seem like a novelty right now, but the technology has the potential to disrupt entire business models. According to onlinecareertips.com, drones could create over 100,000 jobs in the U.S. and have an $82 billion economic impact by 2025.(1)

Until recently, the military ruled the Unmanned Aerial Vehicle (UAV) scene, using them for combat, training and logistics. They’ve been leveraging drones way before Amazon got into the game. In fact, the U.S. Marines have already been using unmanned cargo helicopters for their logistics needs. Now, companies that rely on trucks can start to leverage larger drones to move their inventories from one warehouse to another.

Drones are peaking the interests of private companies and well-established organizations. With a name like Tacocopter, you can imagine the fun service this start-up provides—taco delivery. But it’s not just start-ups toying with drone technology, even well-established organizations like Switzerland’s postal service, the Swiss Post, are testing out drones. Currently, Swiss Post is testing a laboratory transport service between hospitals with drone technology.

“Extended backward with late-stage custom packaging and forward with omnichannel delivery options like Uberization and drones, logistics could become the sexiest job in supply chain.”

“Extended backward with late-stage custom packaging and forward with omnichannel delivery options like Uberization and drones, logistics could become the sexiest job in supply chain.”

—Kevin O’Marah “Future of Work: Four Supply Chain Careers for 2025” on Forbes.com

2. Predictive Modeling

Many companies are increasingly relying on GPS-based tracking systems and automation to keep their business processes running smoothly. Leveraging the internet of things, cloud-based software and big data analytics, organizations are able to use predictive modeling to anticipate problems before they arise and identify new opportunities to streamline their business.

By leveraging multiple technologies, organizations are also making this process more transparent with their customers—providing them with online and mobile applications to track the status of their orders. This transparency has been implemented by traditional package delivery services, but also made the jump into food delivery.

This technology easily translates to different industries which reduces customer service calls and associated costs. Now, the logistics manger has become a driver for customer satisfaction and has made themselves a vital part of their organization.

3. 3-D Printing

You probably already know how much 3-D printing is revolutionizing the manufacturing industry, which is a great thing for logistics managers.

3-D printing is one of the newer tools in a logistics manager’s arsenal. Now, logistics pros can print parts or supplies on demand, as their organization needs them. The 3-D printer is quickly becoming as commonplace as a laptop.

Items that once required extensive labor to produce or source can be created in a single operation by a machine that sits on a desk. A 3-D printer can perform this operation without supervision and have items ready for employees in the morning.

Now, logistics managers can make sure their company has the parts they need by printing them. No last minute panic, no couriers.

4. Sustainability

Sustainable logistics and sustainable profitably go hand-in-hand, creating a win-win-win scenario for companies, customers and the environment.

Making sure trucks are full, identifying more efficient routes, anticipating inclement weather, off-setting trucks with drones, rail or electric vehicles, and warehousing closer to customers are all logistics functions that contribute to a more sustainable business model.

Each mile a trucking fleet takes represents energy costs for the organization and an emissions burden on the planet. By using new technologies like drones, predictive modeling, cloud-based applications, big data analytics and 3-D printing, organizations are able to reduce waste and resource consumption. By optimizing one facet of an organization, it creates a domino effect that can positively impact other parts of the organization as well as the environment.

“Since 2002, P&G has more than halved the impact it has on the environment across energy usage, CO2 emissions, waste disposal and water usage. These operational results have led to nearly $1 billion in cost savings, representing an important contribution to our bottom line.”

“Since 2002, P&G has more than halved the impact it has on the environment across energy usage, CO2 emissions, waste disposal and water usage. These operational results have led to nearly $1 billion in cost savings, representing an important contribution to our bottom line.”

—Huw Water, Proctor & Gamble’s product supplier for the UK “Supply Chain of the Future: Sustainable Logistics and Probability Go Together” in The Guardian

5. Military

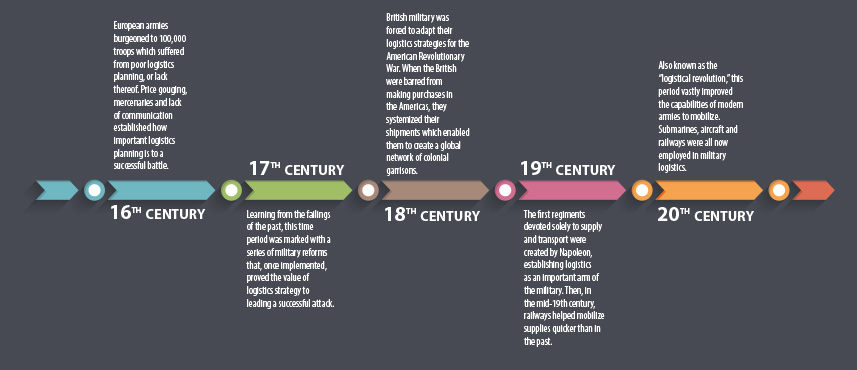

This one is fairly obvious, but not so obvious is how crucial logistics managers are to a successful military operation. Today’s military relies on an estimated 47,000 civilian contractors. It’s been said that the entire military-industrial complex owes its roots to logistics strategies. Imagine getting thousands of troops and all their supplies overseas in a short amount of time. This is something that logistics managers are able to strategically maneuver.

Military logistics is more than supplying the troops; it also involves transporting personnel, medical and health service support, facility acquisition, construction and maintenance, evacuation support and many other important aspects. Logistics directly relates to having an efficient fighting force.

Military logistics also requires adaptation strategies. Unstable areas can complicate a military logistics operation. Logistics managers have to contend with terrorist uprisings, disease outbreaks and hostile governments as well as multiple agencies involved with the operation. That is why joint logistics is key to anticipating challenges and finding collaborative solutions, helping facilitate a globally agile military.

6. Disaster Relief

Logistics is one of the most important facets of a disaster relief operation, as it’s one of the major tools for disaster preparedness.

Logistics managers are responsible for devising emergency response plans so their organization is prepared to mobilize on short notice. This is an in-demand skillset that can be applied to many different industries as well.

Disaster relief logistics managers rely heavily on software and mathematical models to identify the most appropriate areas to set up their warehouses. Their goal is to mobilize supplies as quickly as possible and get them into the hands of those affected by the disaster.

Warehousing, resource allocation, procurement, tracking and transportation are all directly connected to saving lives. Coupled with unpredictable demand, scarce intel, a hazardous work environment and short lead times, disaster relief can be a very challenging but rewarding logistics career.

Disaster relief logistics relates to military logistics in a number of ways, including the need to have an understanding of the political climate of the affected area and how that will affect the operation. Coordination among multiple agencies is another major factor for disaster relief operations, which can either help or hinder the operation.

A Brief History of Military Logistics

Companies Love Logistics Majors

Logistics majors are often the behind-the-scenes problem solvers that keep organizations moving. Many companies have completely transformed entire industries thanks in part to how they tackle logistics. Think Amazon and UBER.

Here are four reasons organizations value logistics majors:

1. They Save You Money

Accountants love people who are good at logistics because logisticians help keep the organization’s balance sheet in check. Logisticians help ward off excess inventory by diligently keeping track of what products are going out to customers and what orders are coming in. They find that goldilocks zone where just the right amount of inventory is on hand—not too much, but not too little.

2. They Save You Money

If employees have to wait on raw materials to do their jobs, the organization grinds to a halt, costing the company money. Logisticians make sure the team has what they need when they need it so work progresses smoothly. No CEO wants to pay employees to sit around and wait for materials.

3. They Save You Money

If the sales team isn’t able to sell off an organization’s inventory, many companies are forced to sell their remaining products at a discount. To avoid taking a loss on production, logisticians are able to liaison between the production team and the sales team to ensure the company avoids financial losses from unloading products at a discount.

Because of the value logistics majors bring to their organizations, they are poised to become chief operating officers or chief technology officers.

4. They Save You Money

Logistics is all about creating efficiencies, and efficiencies mean cost savings. Re-routing a fleet from a storm system, making sure to avoid having an empty truck and diversifying transportation methods all save a company fuel, maintenance and inventory costs. Logistics managers are good at solving problems before they become one. They are intuitive and excellent at deductive reasoning—skills that optimize business operations.

Give to Florida Tech

Give to Florida Tech