Designing and Making a Prototype: A Guide to How to Manage Making Projects

- Preliminary concept drawing sketch(es)

- Faculty Only: A thorough literature review of the journal literature, patent literature, and company websites

- Crude model: Cardboard, styrofoam, clay, wood, etc.

- Refined concept drawing(s) for product/process design

- Preliminary parts list (most critical parts, suppliers, and costs)

- Decision matrix to choose between concept drawing options

- Design Meeting 1: Get approval for all items concepts; order critical parts

- CAD drawings of most critical parts & rough draft of assembly diagram

- Faculty Only: Wiring diagram drawing (not necessarily yet in KiCAD)

- Faculty Only: Process flowsheet

- Faculty Only: Piping and instrumentation diagram (P&ID)

- 1st Bill of Materials with vendors and prices

- Design Meeting 2: Get approval for all items up to now; order all remaining parts

- Iterate on all prior items

- CAD drawings of all parts

- 3D print, laser cut, machine parts - v. 1

- Breadboard level testing of wiring diagram

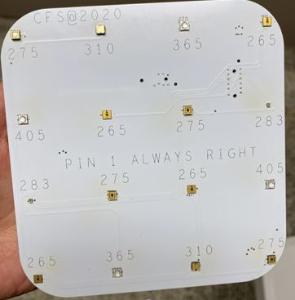

- KiCAD level wiring diagram

- Write block diagram "pseudocode" for each subprocess and a system-level diagram to call each subprocess

- Design Meeting 3: Get feedback on all items up to now; status update and hopefully delivery of all ordered items

- Write the computer code corresponding to 19) or subcontract that out

- If time available after 17) working: Order bare printed circuit boards (PCBs) from AllPCB.com (turnaround time from China is about 10 days)

- Fill in final report appendixes of all prior work in form of PowerPoint slides with goal to fill in as many blanks as quickly as possible and identify what hasn't been done

- Record Slide Show function in PowerPoint (PPT) one slide at a time

- Transcribe recorded narration into figure captions for report and then paste link the PPT figures into the Word report using either Transcribe or Otter (Otter's Pro version for faculty).

- Revise all diagrams to adjust for fit and finish

- 3D print, laser cut, machine parts - v. 2

- Solder parts as necessary, if reasonable to do so

- Video/photograph all assembly processes (hyperlink these into report appendixes)

- If time available: Use GoDaddy.com to convert text-based bare bones web site into something presentable to outside world

- If time available: Have US PCB manufacturer (Jaycon Systems? If so, ask for Anthony Li at anthonyli@jayconsystems.com.) install parts onto "bare" PCB from AllPCB.com

- If time available: Have US PCB manufacturer consult on converting existing work to be better ready for manufacturing

- Design Meeting 4: Review of all prior work; assess what needs to be done prior to showcase

- Test computer code at subsystem level

- Iterate on all prior items

- Prepare a cost analysis as a function of the number of items manufactured as laid out in the Bill of Materials, economicsbycategory, and mastereconomicsanalysis spreadsheets of the CFSeconomics2.xlsx attachment that Dr. Brenner prepared for his small business, Chem-Free Solutions, that evolved out of his teaching The Basics of Making course

- Test computer code and product at full system level

- Convert recorded PPT narration into text for report draft

- Fill PPT slides into standard poster template

- Prepare 5 minute video of entire project for "e-poster" to play in background at poster presentation and for web site

- Final poster/product display for showcase

- Incorporate feedback from showcase into final version of report

- Convert the recorded PPT slides into .mp4 format

- Ask the professor to transcribe the .mp4 into the rough draft of a final report using Otter.ai Pro

Give to Florida Tech

Give to Florida Tech