Peroxide Forming Chemicals

- Introduction to Peroxides

- Overview

- Conditions that cause peroxide formation

- Indicators of peroxide formation

- Storage and Handling

- Controlling Peroxide Formation

- Peroxide Classification & Retention Times

- Evaluating & Testing for Peroxides

- Known Peroxide Forming Chemicals

- References

Introduction to Peroxides

Overview

Peroxide-forming chemicals are a class of compounds that have the ability to form shock-sensitive explosive peroxide crystals when exposed to various storage conditions or extended storage times. These peroxide crystals can violently detonate when subjected to: thermal and mechanical shock, impact and friction, or combined with other compounds. Other compounds polymerize unsaturated compounds and can initiate a runaway, explosive polymerization reaction. The rate at which peroxides form is compound dependent and is classified into three groups (A-C) related to the inherent dangers. More on classification is described below.

Conditions that cause peroxide formation

Factors that affect the rate of peroxide formation include exposure to: air, light and heat, moisture, and contamination from metals. Some Peroxide-forming chemicals react with oxygen, even at low concentrations, to form peroxy compounds. Since some peroxide-forming chemicals are packaged in atmospheres containing oxygen, even unopened containers can eventually form peroxy compounds. Therefore it is important to pay close attention to chemicals expiration date and to immediately dispose when expired; specifics on storage is discussed in below.

Evaporation and distillation increases the risk of peroxide formation. In general, the faster the chemical evaporates, the greater its hazard, since evaporation of the chemical allows the peroxide to concentrate and form crystals. Even slow evaporation still exhibits a concern and should be periodically checked for peroxide formation.

Manufacturers may add an inhibitor to peroxide forming chemicals to counter peroxide formation. Butylated hydroxy toluene (BHT), hydroquinone, and diphenylamine are some examples. Over time, these inhibitors can become exhausted allowing peroxides to form. Distilling the solvent can completely remove the inhibitors and make the solvent immediately susceptible to peroxide formation.

Indicators of peroxide formation

Peroxide formation becomes evident when crystalline solids are observed in the liquid itself or around the bottle’s cap. Some peroxide-forming chemicals produce solutions that appear cloudy. Peroxide crystals may form on the container plug or the threads of the lid and detonate when the lid is twisted. Do not open a liquid organic peroxide or peroxide-forming chemical if crystals or a precipitate are present.

Storage and Handling

Controlling Peroxide Formation

Peroxide formation can be controlled by adhering to the following methods:

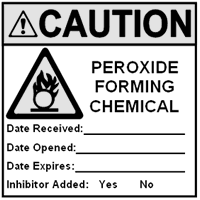

- Label the container with the date of purchase and the date of the most recent test for peroxides. See appendix B for printable peroxide label.

- Containers should be dated when opened and tested periodically for the presence of peroxides. Do not exceed storage time limits.

- Many chemical companies now routinely print an expiration date on containers of the worst peroxide formers.

- Peroxide-forming chemicals should be purchased in small quantities, and the older material in the inventory should be used first.

- Solvents containing low levels of free radical scavengers such as BHT should be used whenever the presence of the stabilizing species does not interfere with intended application.

- However, be aware, that these free radical inhibitors will be depleted over time as peroxides are formed.

- Distillation often removes the inhibitors and therefore more should be added to the manufacturer’s recommended concentration.

- Keep peroxide forming chemicals away from sources of ignition and store in a cool, dry place.

- Store protected from moisture, light and air.

- Store peroxides at the lowest possible temperature consistent with their solubility and freezing point.

- Peroxide forming compounds should not be stored at or lower than the temperature at which the peroxide freezes or precipitates, as this will make these compounds extremely sensitive to shock.

- Store in tightly closed containers and keep in a marked flammables area.

- All peroxide-forming solvents should be checked for the presence of any peroxides prior to distillation or evaporation.

- Most explosions occur when a material is distilled to dryness

Peroxide Classification & Retention Times

- Class A: Peroxide Hazard on Storage – Without Concentration.

- Test for peroxide formation before using or discard 3 months after opening and 12 months if unopened.

- Example: Sodium amide

- Class B: Hazard Due to Peroxide Concentration.

- Test for peroxide formation before distillation or evaporation.

- Test for peroxide formation or discard 6 months after opening or 12 months if unopened.

- Example: Tetrahydrofuran

- Class C: Auto Polymerize as a Result of Peroxide Accumulation.

- Test for peroxide formation prior to use or discard after 12 months if unopened.

- Example: 2-butanol

- Class D: May Form Peroxides but cannot be clearly placed in Class A-C

See appendix A for a comprehensive list of peroxide forming chemicals.

Evaluating & Testing for Peroxides

- Examine container for contamination: Crystals tend to form on the inner surfaces of the container in the form of ice like structures, crystals, solid masses or an obscure cloudy medium signify gross contamination. Wisp like structures floating in a clear liquid suspension signify contamination as well an oily viscous layer present in the material. Visible discoloration and liquid stratification are additional indicators of peroxide formation.

- If you do not see crystals, or if the container is metal or opaque, proceed to the next step.

- Determine whether it is safe to test for peroxides: If the contents of the container have evaporated to less than 10% of the original volume, do not test for peroxides as it is too high of a risk and contact the Office of Environmental Health and Safety. If you do not know the history of the chemical, you can test its contents if it is one of the following:

- Class A hazard: opened and <6 months old; or unopened and <1 year old.

- Class B hazard: opened and <1 year old; or unopened and <2 years old.

- Class C hazard: opened and <2 years old; or unopened and <3 years old.

- Test for Peroxides: Several methods are available to test the presence of peroxides in organic solvents, with direct-reading test strips being the most common. The EH&S office will provide test strips in emergency situations, yet routine monitoring of stored chemicals fall upon the PI to provide his/her own test equipment. Peroxides are most often reported in ppm with 100 widely used as a general control point for disposal. Florida Tech’s peroxide cutoff is at or above 80 ppm and should be marked for disposal and EH&S contacted. Peroxide concentration at 50 – 79 ppm should be marked for concern and EH&S notified.

Known Peroxide Forming Chemicals

|

Class A |

|

|

Butadienea |

Tetrafluoroethylenea |

|

Vinylidene chloride |

Methacrylate |

|

Chloroprenea |

Divinylacetylene |

|

Sodium amide (sodamide) |

Potassium amide |

|

Potassium metal |

|

|

Class B |

|

|

Acetal |

4-heptanol |

|

Acetaldehyde |

Methyl acetylene |

|

Benzyl alcohol |

Methyl isobutyl ketone |

|

Isopropyl ether |

3-methyl-1 butanol |

|

Cyclohexanol |

Methyl cyclopentane |

|

2-cyclohexen-1-ol |

2-pentanol |

|

Cumene |

4-penten-1-ol |

|

Decahydronaphthalene |

1-phenylethanol |

|

Diacetylene |

2-phenylethanol |

|

Dicyclopentadiene |

2-propanol (isoproranol, “IPA”) |

|

Diethyl ether |

Tetrahydrofuran |

|

Diethylene glycol |

Tetrahydronaphthalene |

|

Dimethyl ether |

Vinyl ethers |

|

Dioxanes |

Other secondary alcohols |

|

Ethylene glycol dimethyl ether |

|

|

Class C |

|

|

Acrylic acidb |

Stryene |

|

Acrylonitrileb |

Vinyl acetate |

|

Butadienec |

Vinyl acetylene |

|

2-butanol |

Vinyl chloride |

|

Chloroprenec |

Vinyl pyridine |

|

Chlorotrifluoroethylene |

Vinyladiene chloride |

|

Methyl methacrylateb |

Tetrafluoroethylenec |

|

Class D |

|

|

Acrolein |

1,3-Dioxepanedd |

|

Allyl etherd |

Di(1-propynl) etherf |

|

Allyl ethyl ether |

Di(2-propynl) ether |

|

Allyl phenyl ether |

Di-n-propoxymethaned |

|

p-(n-Amyloxy)benzoyl chloride |

1,2-Epoxy-3-isopropoxypropaned |

|

n-Amyl ether |

1,2-Epoxy-3-phenoxypropane |

|

Benzyl n-butyl etherd |

p-Ethoxyacetophenone |

|

Benzyl etherd |

1-(2-Ethoxyethoxy)ethyl acetate |

|

Benzyl ethyl etherd |

2-Ethoxyethyl acetate |

|

Benzyl methyl ether |

(2-Ethoxyethyl)-a-benzoyl benzoate |

|

Benzyl-1-napthyl etherd |

1-Ethoxynaphthalene |

|

1,2-Bis(2-chloroethoxyl)ethane |

o,p-Ethoxyphenyl isocyanate |

|

Bis(2-ethoxyethyl)ether |

1-Ethoxy-2-propyne |

|

Bis(2-(methoxyethoxy)ethyl) ether |

3-Ethoxypropionitrile |

|

Bis(2-chloroethyl) ether |

2-Ethylacrylaldehyde oxime |

|

Bis(2-ethoxyethyl) adipate |

2-Ethylbutanol |

|

Bis(2-methoxyethyl) carbonate |

Ethyl-b-ethoxypropionate |

|

Bis(2-methoxyethyl) ether |

2-Ethylhexanal |

|

Bis(2-methoxyethyl) phthalate |

Ethyl vinyl ether |

|

Bis(2-methoxymethyl) adipate |

Furan |

|

Bis(2-n-butoxyethyl) phthalate |

2,5-Hexadiyn-1-ol |

|

Bis(2-phenoxyethyl) ether |

4,5-Hexadien-2-yn-1-ol |

|

Bis(4-chlorobutyl) ether |

n-Hexyl ether |

|

Bis(chloromethyl) ethere |

o.p-Iodophenetole |

|

2-Bromomethyl ethyl ether |

Isoamyl benzyl etherd |

|

beta-Bromophenetole |

Isoamyl etherd |

|

o-Bromophenetole |

Isobutyl vinyl ether |

|

p-Bromophenetole |

Isophoroned |

|

3-Bromopropyl phenyl ether |

b-Isopropoxypropionitriled |

|

tert-Butyl methyl ether |

Isopropyl-2,4,5-trichlorophenoxy acetate |

|

n-Butyl phenyl ether |

n-Methylphenetole |

|

n-Butyl vinyl ether |

2-Methyltetrahydrofuran |

|

Chloroacetaldehyde diethylacetal |

3-Methoxy-1-butyl acetate |

|

2-Chlorobutadiene |

2-Methoxyethanol |

|

1-(2-Chloroethoxy)-2-phenoxyethane |

3-Methoxyethyl acetate |

|

Chloroethylene |

2-Methoxyethyl vinyl ether |

|

Chloromethyl methyl ether |

Methoxy-1,3,5,7-cyclooctatetraene |

|

b-Chlorophenetole |

b-Methoxypropionitrile |

|

o-Chorophenetole |

m-Nitrophenetole |

|

p-Chlorophenetole |

1-Octene |

|

Cyclooctened |

Oxybis(2-ethyl acetate) |

|

Cyclopropyl methyl ether |

Oxybis(2-ethyl benzoate) |

|

Diallyl etherd |

b,b-Oxydipropionitrile |

|

p-Di-n-butoxybenzene |

1-Pentene |

|

1,2-Dibenzyloxyethaned |

Phenoxyacetyl chloride |

|

p-Dibenzyloxybenzened |

a-Phenoxypropionyl chloride |

|

1,2-Dichloroethyl ethyl ether |

Phenyl-o-propyl ether |

|

2,4-Dichlorophenetole |

p-Phenylphenetone |

|

Diethoxymethaned |

n-Propyl ether |

|

2,2-Diethoxypropane |

n-Propyl isopropyl ether |

|

Diethyl ethoxymethylenemalonate |

Sodium 8-11-14-eicosatetraenoate |

|

Diethyl fumarated |

Sodium ethoxyacetylidef |

|

Diethyl acetald |

Tetrahydropyran |

|

Diethylketenef |

Triethylene glycol diacetate |

|

m,o,p-Diethoxybenzene |

Triethylene glycol dipropionate |

|

1,2-Diethoxyethane |

1,3,3-Trimethoxypropene |

|

Dimethoxymethaned |

1,1,2,3-Tetrachloro-1,3-butadiene |

|

1,1-Dimethoxyethaned |

4-Vinyl cyclohexene |

|

Dimethylketenef |

2,4,5-trichlorophenoxyacetate |

|

3,3-Dimethoxypropene |

Vinylene carbonate |

|

2,4-Dinitrophenetole |

Vinylidene chloridedd |

Key:

a When stored as a liquid monomer.

b Although these chemicals form peroxides, no explosions involving these monomers have been reported.

c When stored in liquid form, these chemicals form explosive levels of peroxides without concentration. They may also be stored as a gas in gas cylinders. When stored as a gas, these chemicals may autopolymerize as a result of peroxide accumulation.

d These chemicals easily form peroxides and should probably be considered under Part B.

e OSHA - regulated carcinogen.

f Extremely reactive and unstable compound.

References

- Stephen F. Austin State University: Peroxide-forming Chemicals

- University of Washington: EH&S Guidelines for Peroxide Forming Chemicals

- Local Hazardous Waste Management Program in King County, Washington: Best Management Practices for Monitoring Peroxide-Forming Compounds Prior to Disposal

- sigmaaldrich.com: Peroxide Forming Solvents

- University of Connecticut: Peroxide-Forming Compounds – Safe Work Practices

- Vanderbilt University: Peroxide Forming Chemicals: Management, Retention and Storage

- Stanford University: Information on Peroxide-Forming Compounds

- University of Hawai’i, Mānoa: Storage and Handling of Peroxide Forming Chemicals

- Baylor University: Peroxide Forming Chemicals

Give to Florida Tech

Give to Florida Tech